Choose the best fully-autonomous cleaning robot for your project with PVRADAR

How do you select the most cost-effective cleaning robot for your project? In places with heavy soiling, fully autonomous robots are a viable solution to keep soiling losses under control. But which one should you choose from the wide range on the market? The cheapest, fastest, most efficient or the most durable? Using PVRADAR, we show how five different fully autonomous robotic solutions work in a sample project in Chile.

Soiling losses put the economic viability of solar projects at risk.

Utility-scale projects move into desert areas, where soiling losses are higher and so are the cleaning needs. Site measurements have shown significant efficiency drops for these locations. "The Middle East, for example, has the worst dirt build-up regions, with peak losses ranging from 10% to 70%" [1].

Fully autonomous cleaning robots keep the plant clean at all times.

Fully-autonomous robots are becoming a standard solution because of their ability to clean the entire power plant with a very high frequency. In consequence, soiling losses are reduced to almost zero. On top of that, the technology has further upsides:

- no permanent labour required

- savings in water and fuel consumption

- validated in numerous projects

The market offers many different options. PVRADAR helps you choose the right one.

Some robots are faster, some are cheaper, others are more efficient. Depending on the project and site conditions the economic evaluation changes and different aspects come into play. PVRADAR integrates technical simulation and economic evaluation of a wide range of cleaning solutions. This allows us to identify the added value of the different aspects of fully-autonomous cleaning robots over the entire lifetime of a project.

Five robots were evaluated for a typical plant in the Chilean Atacama Desert.

The analysis is performed for a theoretical 230MWp generic plant located in the Atacama Desert, a dry and dusty area. The severity of soiling at the project location is defined based on 20 years of historical satellite data. Based on PVRADAR’s proven statistical approach, three soiling level scenarios can be compared: P10 (optimistic), P50 (best-guess) and P90 (conservative). For this specific example we have considered the "best-guess" scenario.

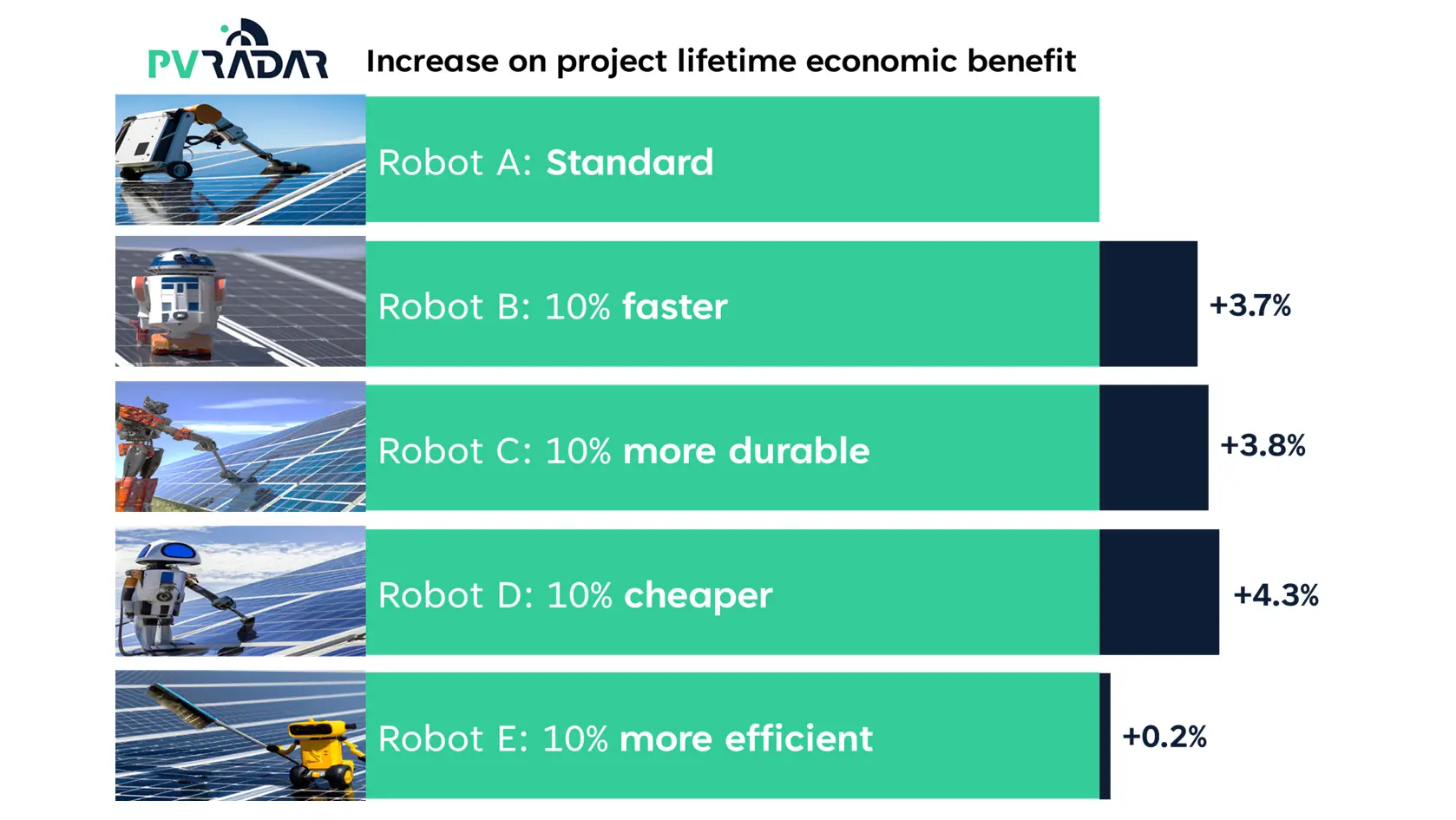

Five different robots are being compared. The first one representing the baseline, and four variations, each of which excels in one aspect. Can you guess which one will be the most cost-effective?

- Robot A: Standard robot

- Robot B: 10% faster

- Robot C: 10% more durable

- Robot D: 10% cheaper

- Robot E: 10% more efficient

A single difference can significantly increase profitability.

Our results show that the PV plant is exposed to a 10.8% of yearly soiling losses in average, if no cleaning is performed. This means more than 20.0 MEUR in losses for the entire lifetime of the project.

PVRADAR simulated the performance and estimated the lifetime cost of each robotic cleaning system and compared them in terms of Net Present Value (NPV). Our base-case, Robot A, generates a positive NPV of 12.3 MEUR compared to no cleaning. The different variants were then simulated and their impact compared with the base case technology.

- Little surprising, price had the biggest impact with a 10% decrease in cost resulting in a 4.3% higher NPV.

- Increasing the speed or durability by 10% led to a 3.7% and 3.8% higher NPV, respectively. The similarity between both is due to the fact that higher speed translates into fewer operating hours spent and, thus an increase in the lifetime of the technology.

- In contrast, a 10% higher efficiency did not significantly improve the business case, which suggests that efficiency has a lower relevance compared to the other aspects for this example.

PVRADAR allows project specific evaluations.

It is worth noticing that these results are specific for this example and should not be considered as general conclusions. In real life, every cleaning robot comes with its unique set of technical features and costs. Every project is different and both site conditions and project financials impact the technology selection.

If you are interested in finding the right technology for your project, contact us!

References

[1] Smestad, G.P., Germer, T.A., Alrashidi, H. et al. Modelling photovoltaic soiling losses through optical characterization. Sci Rep 10, 58 (2020). https://doi.org/10.1038/s41598-019-56868-z