Soiling Measurement Guide Part 2/2: Common issues and how to avoid them

Thore Müller, 23.07.2024.

Soiling refers to the difference in electrical output between two photovoltaic devices: one "clean" and one "dirty." These devices are installed such that the only difference in their (corrected) measurements is the amount of light blocked or scattered due to soiling.

In Part 1 of this series, I outlined my approach to choosing the right measurement principle ("electrical" or "optical") and soiling sensor.

My top 3 sources of measurement error

Based on my experience, the three main sources of measurement error are:

- Unstable measurement conditions

- Human error

- Unexpected environmental influences

Below, I provide examples from my experience and offer recommendations based on the lessons I've learned.

Source #1: Unstable measurement conditions

For an electrical sensor or measurement, the soiling level is calculated as the relative difference between the temperature-corrected output of the clean and dirty module or reference cell. However, the comparison is only valid if:

- The temperature is either known or equal for both devices.

- The irradiance is high and stable.

To satisfy both these conditions, sensor manufacturers (and myself) recommend using measurements from clear-sky days only and either filtering data for two or three hours around noon or applying a minimum irradiance condition (here 700 W/m²).

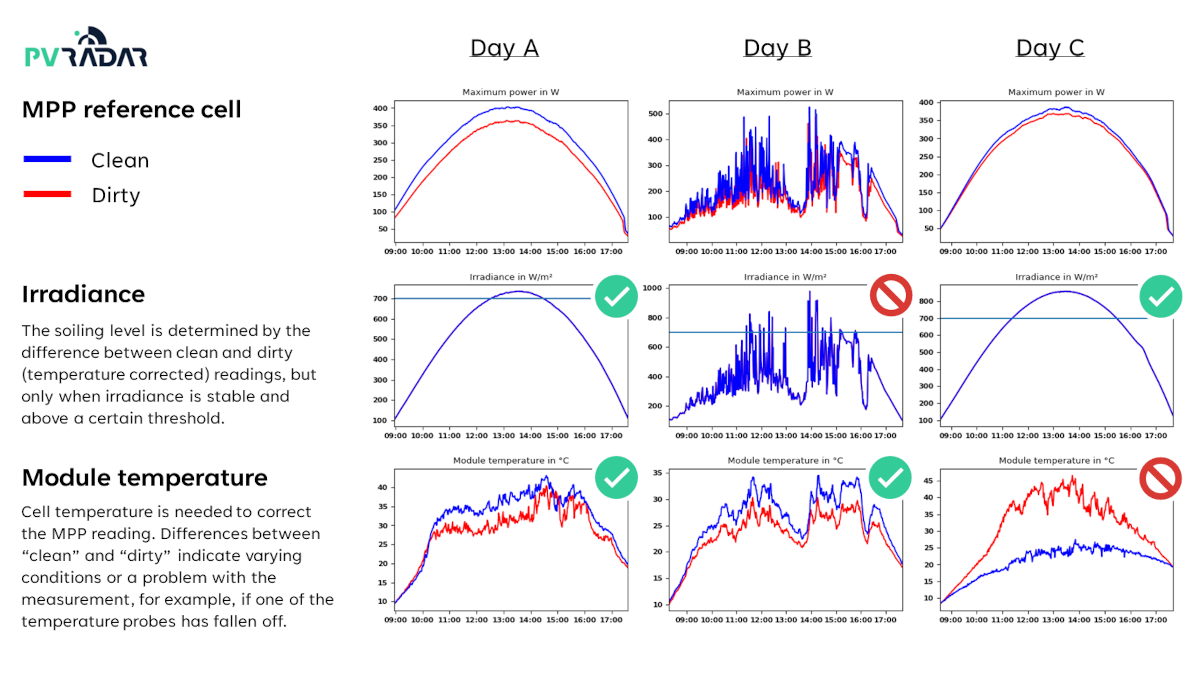

The image below shows the maximum power output, irradiance, and cell temperature from a measurement taken in Chile. The measurement is based on two full-size modules that were both installed on the same structure.

As we can see, only one of the three days shown here meets both requirements:

- Day A shows stable irradiance and plausible cell temperatures.

- Day B shows unstable irradiance conditions for most of the day.

- Day C shows significant temperature differences between the clean and dirty module.

Maximum power output, irradiance, and cell temperatures from two full-size modules measured in Chile.

What is interesting in this example is that even for Day A there are differences in the temperature of the "clean" and "dirty" modules, which emphasizes the importance of having one temperature probe on each module for proper correction (one probe on one of the modules would not have been enough!).

On the contrary, I believe that a single irradiance measurement is sufficient as it can be expected that (front side!) irradiance is the same for two modules installed a few meters apart and at the same angle and orientation. However, for the rear-side irradiance, this may be an entirely different story.

In this case, the significant temperature difference on Day C was due to the fact that the probe of the clean cell had fallen off. Based on my experience, such issues are quite common and often go undetected for several weeks. This means that no reliable results can be calculated for the entire affected period.

My Recommendations for Good Measurements

- Regularly review measurement data: Ensure you consistently monitor the data throughout the measurement campaign to identify and correct any issues or unforeseen events. Ideally, you should have direct access to the data via VPN or a web platform from which you can download the data.

- Always measure irradiance: The soiling level is determined by the difference between clean and dirty (temperature-corrected) readings, but this is only valid when irradiance is stable and above a certain threshold. Use the measured irradiance to filter the data.

- Measure the cell temperature of both clean and dirty references: Cell temperature is necessary to correct the power (MPP) or short circuit current (ISC) reading. Differences between "clean" and "dirty" indicate varying conditions or a potential problem with the measurement.

- Keep the raw data: Some measurement systems automatically calculate soiling metrics at the end of each day. While I prefer to perform the analysis myself, I always advice retaining the raw data for verification and detailed analysis.

- Clean the "clean" device in the morning: Ensure that nothing affects the measurement during the critical period around noon or when the irradiance is above the threshold. Cleaning at the end of the day invalidates the measurement because the "clean" reference was not actually clean during the measurement period.

- Avoid measuring soiling using bifacial modules: The problem with bifacial modules is that their rear-side irradiance is always inhomogeneous and might differ for the "clean" and "dirty" references even if they are installed close by (e.g., due to a shadow from the structure) or cannot be accurately captured by a single rear-side measurement point. If you need to measure soiling on bifacial modules (for example, because you want to use two of the power plant's own modules), make sure that both modules are side by side in the middle of the tracker or structure. Do not combine a bifacial module with a reference cell. In that case, I personally prefer to cover the rear side of the bifacial module with a black plastic sheet or vinyl. Yes, this might change the cell temperature, but it is easier to correct for that than for the uneven distribution of rear-side irradiance.

Source #2: Human error

In many cases, the person designing the measurement system and responsible for data analysis is not the same person who performs the maintenance. Often, there is a significant difference in background and personal interest in the measurement campaign. Based on my experience, a measurement system should be designed so that its maintenance is self-explanatory and could be performed by a 5-year-old child.

- Place sensors in easily accessible locations: I have encountered cases where maintenance personnel did not clean the clean reference because it appeared clean to the eye and was located in a place that required carrying a steel ladder for several minutes to reach it.

- Clearly mark which cell or module is to be cleaned and which part is to be left dirty: Especially in low-soiling environments or after some rain, it might not be obvious which one is to be cleaned.

- Ensure both cells are sufficiently far apart so that you can clean one without touching the other: This helps prevent accidental "contamination" (for example from water droplets) of the dirty reference during maintenance.

- Add a button to register maintenance: Provide a switch at the measurement station that maintenance personnel must activate when they start and finish maintenance. This way, you can easily exclude days when measurements may not be reliable.

Photo by Matthew Muller, NREL

Source #3: The Environment

Environmental factors can greatly influence soiling measurements. Consider the following potential sources of error:

- Place your sensor in a representative location: Avoid placing it right next to a dusty road if that road won’t likely affect your power plant in the same way as it affects your measurement.

- Be aware of birds: Bird droppings are a type of soiling, but in my opinion it is not possible to effectively measure their impact with a sensor as it would not get affected the same way as an entire power plant would: The image below shows a sensor placed in an open field, effectively creating the highest point for birds to sit in the entire landscape. This made it a common resting spot for the local bird population. My recommendation is to use bird spikes or similar deterrents to keep birds away from your sensors.

- Clean both references if bird droppings are present: If bird droppings are found on your sensor, clean both the clean and dirty references. Unfortunately, in the same example, the maintenance crew only cleaned the clean reference (as instructed). They should have cleaned both cells (to make sure that the sensor reading describe conditions that the later power plant will experience) and ensured birds don’t return.

- Avoid using reference cells to measure snow losses: Snow affects large modules differently than small reference cells. While this is also true for soiling, the impact is less pronounced. To accurately measure snow losses, use full-size modules installed at the height and angle they would be in a real power plant.

Examples of environmental influences on soiling measurements: Left: Bird droppings on both the clean and dirty reference modules. Right: Snow covering a large module while leaving the reference cells unaffected.

Some general advice: Document everything!

Imagine yourself sitting at your computer a few months from now, looking at your measurement data. I guarantee you, there will be artifacts and data points that you cannot explain: are they soiling? Measurement errors? Issues with the sensor? Just a bird? You might have an idea of what it could be, but what you need is some piece of evidence to support your claim or rule them out.

Therefore, my recommendation is: document everything! One easy way of doing that during the campaign is to take pictures to document the context of your measurements. Make sure to always make them from the same angle and at the same distance every day for consistency. Choose an angle and distance that allows you to clearly see the relevant details in your images, as well as the environment. Finally, make sure the images are not sent via WhatsApp, as it reduces the resolution to the point where the detail you are interested in becomes just a few pixels.