Built for asset managers who don’t like wasting money

For utility-scale PV plants, cleaning decisions directly affect both energy yield and operating costs. Yet in many portfolios, cleanings are still triggered by fixed schedules or reactive thresholds that fail to reflect actual soiling conditions and economics.

This solution is designed for asset managers and O&M teams who want to maximize recovered energy while ensuring that every cleaning action is economically justified, defensible, and scalable across large portfolios.

The challenge: When to clean is an economic question

Soiling conditions evolve continuously and vary from year to year. Fixed, calendar-based cleaning schedules cannot capture this variability and often result in cleanings that are either unnecessary or poorly timed.

Reactive cleaning approaches face a similar limitation. By the time underperformance is visible, the optimal cleaning window may already have passed, leading to missed revenue opportunities.

The fundamental problem is not identifying that soiling exists, but quantifying whether a cleaning action will pay off before it is performed. Without a reliable, data-driven way to estimate economic benefit, cleaning decisions remain far from the optimal.

Our solution: Probabilistic cleaning optimization during operation

PVRADAR Labs provides a customizable workflow for probabilistic, data-driven cleaning optimization based on real-time plant data and powered by PVRADAR’s state-of-the-art soiling model.

Rather than relying on fixed rules, the workflow evaluates cleaning strategies across many historical years and identifies those that maximize economic return under varying conditions. These insights are then used to derive cleaning recommendations for the current year, updated continuously as new data becomes available.

The solution is built on the PVRADAR framework and tailored to each client’s specific requirements, including the availability of soiling measurements, relevant meteorological variables, and details of cleaning costs and operational parameters. Results can be delivered as interactive notebooks, provided through an API, or integrated into custom dashboards showing soiling forecasts, expected energy recovery, and the economic benefit of cleaning actions.

How it works: From data to daily recommendations

1. Forecast future soiling behavior

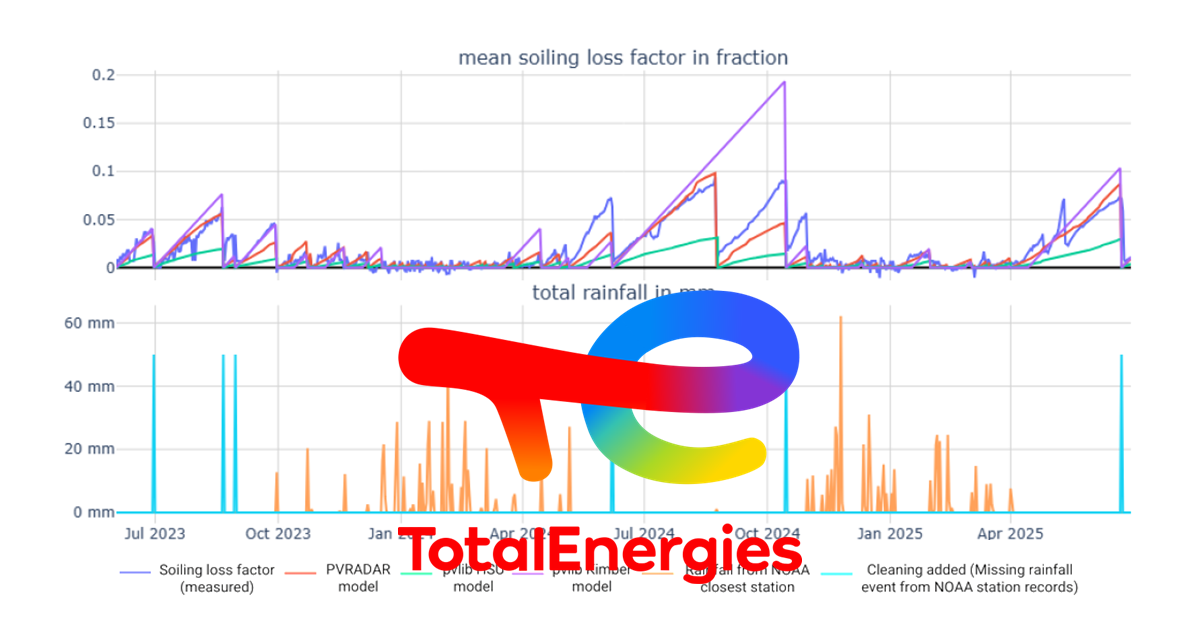

Future soiling is forecast using real-time plant data combined with historical soiling modeled with the PVRADAR soiling model.

2. Optimize cleaning strategies historically

For each historical year, the workflow computes the cleaning schedule that would have maximized economic return.

3. Derive optimal cleaning dates for the current year

Historical strategies are weighted based on similarity in meteorological conditions and soiling patterns to derive optimal cleaning dates for the current year.

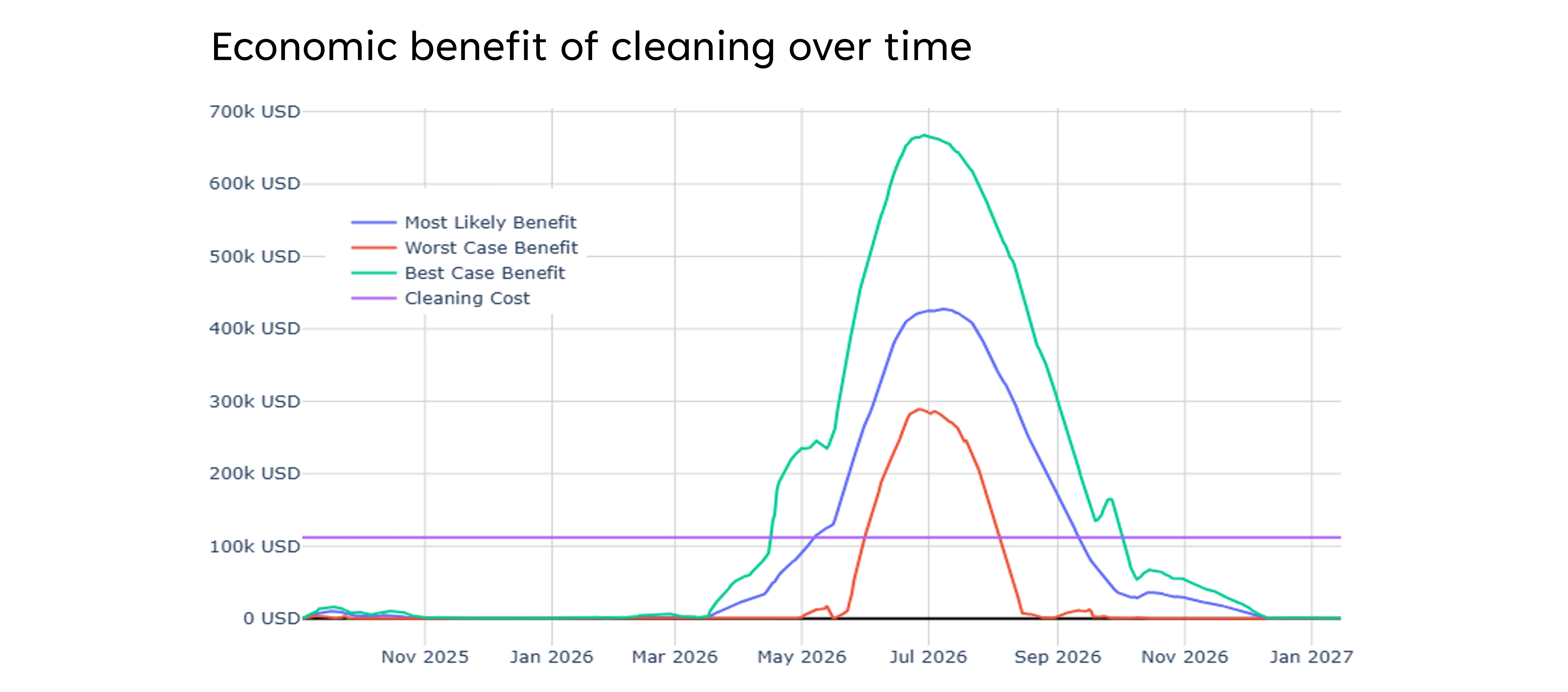

4. Quantify economic benefit before cleaning

The expected economic benefit of cleaning on the optimal date, as well as within the surrounding time window, is quantified to support informed decision-making.

5. Update recommendations continuously

The analysis is repeated daily as new data arrives, ensuring that recommendations remain aligned with current conditions.

What you get: Cleaning decisions you can defend

- Cleaning schedules optimized for economic return rather than fixed rules

- Avoidance of unnecessary or poorly timed cleanings

- Clear quantification of expected energy recovery and economic benefit before action

- A scalable methodology applicable across portfolios and regions

- Transparent assumptions and traceable results for internal and external review